| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : ZT

Model Number : WG300-V-25

Certification : ISO9001:2008

Place of Origin : Foshan, China

MOQ : 1 pcs

Price : negotiable

Delivery Time : Within 25 days after the advance payment is made

Packaging Details : Film and wooden case

Supply Ability : 30 SETS PER MONTH

Application : Separating Ferrous Metals

Capacity : 2-50 t/h

Magnetic Drum Diameter : 500-2000 mm

Magnetic Drum Length : 500-3000 mm

Magnetic Field Intensity : 100-800 mT

Material : Stainless Steel

Motor Power : 1.5-30 kW

Motor Speed : 1400-1700 r/min

Name : Dry Magnetic Separator

Power : 220V/380V

Size : Customized

Type : Magnetic Separator

Weight : Customized

Working Principle : Magnetic Separation

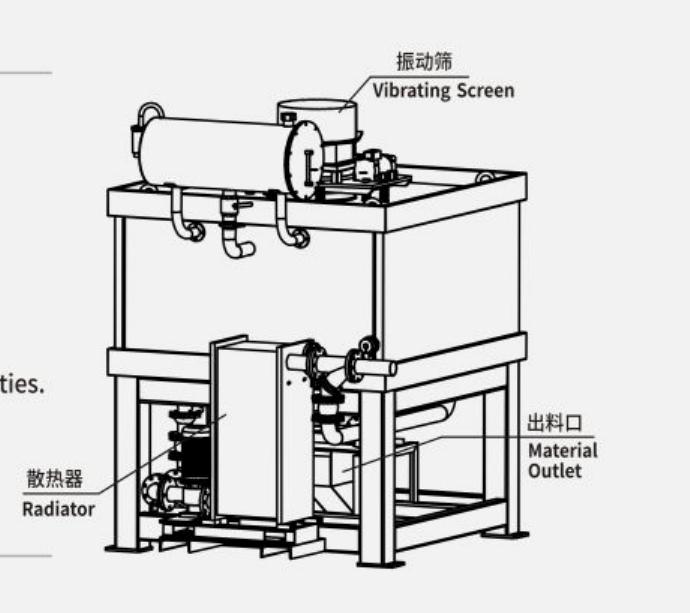

WG300-V-25 high efficiency powder separator with 30000 gauss 2-3 tons/h output capacity

Product features:

The powder high efficiency separator machine is a series of machines developed by our company according to the features of quartz sand, powder and its own technical technical advantages. Compared with the previous electromagnetic dry powder equipment, the equipment has high magnetic field gradient, large contact area of material and magnetic medium, uniform magnetic field distribution, new magnetic medium, better magnetic conductivity and self carrying capacity. The material distribution system and the magnetic field intensity can be adjusted according to the material. It can effectively separate and remove magnetic substances such as iron and titanium in the process.

| Model | Insulation category | Coil power(KW) | Magnetic field(GS) | Pipe size(in) | Capacity(t/h) | Weight(KG) | Dimension(mm) |

| WG300-V-25 | E | 25 | 0-30000 | 6 | 2-3 | 16000 | 2868*2382*3091 |

| WG430-V-50 | 50 | 0-30000 | 8 | 4-6 | 22000 | 3140*2680*3300 |

Operation Steps

Feed the dry powder from the hopper, meanwhile make the separator state at the magnetizing and run a vibrator. After a period, stop feeding, cut off the magnetic device, run the other vibrator (keep the two vibrator running), poke the raffle of drain of material funnel into the iron discharge. Then discharge the magnetic material absorbed on the magnetic media relying on the vibrating force.

Application

Electromagnetic high efficiency dried-powder separators are applied in process the fine mineral particle, the magnetic fine ferrous mineral particle such as hematite, martite, limonite, siderite, chromite, polianite; and also fine nonferrous metals mineral particle, for example wolframite; fine rare earth mineral particle, for example eremite; and fine nonmetallic mineral particle such as feldspar, quartz, kaoli.

|

|

High Efficiency Magnetic Separation Equipment Output Capacity Quartz Medicine Powder Feldspar Chemical Images |